Metal Clad PCB

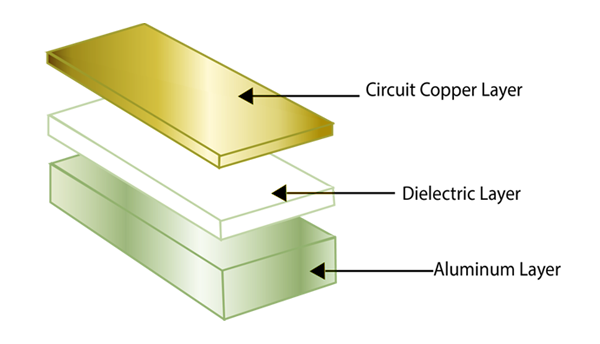

Metal Clad Printed Circuits Boards (or MCPCB) are typically manufactured using either aluminium or copper as the base substrate of the PCB. The key advantage of a metal clad PCB is the heat management of the assembled PCB. The metal becomes the principal component for heat removal from the device. By using a MCPCB better thermal efficiency is gained, thus allowing removal of large heat sinks from the assembly, plus possible downsizing of the design.

The advantages of using a Metal Clad PCB can be defined as follows;

- MCPCBs can be milled and bent to form shapes not achievable with standard glass fiber and ceramic PCBs.

- Components are kept cool, thus increasing life.

- Efficient assembly can be achieved with automation, no need for labor intensive bolt on heat sinks.

- Power densities can be increased without increased heat to the component.

- Insulation requirements are achieved by dielectrics specific to the final application.

- Better cooling of components will increase reliability in the field.

Metal Clad Printed Circuit Boards are used for LED lighting applications and power conversion applications.